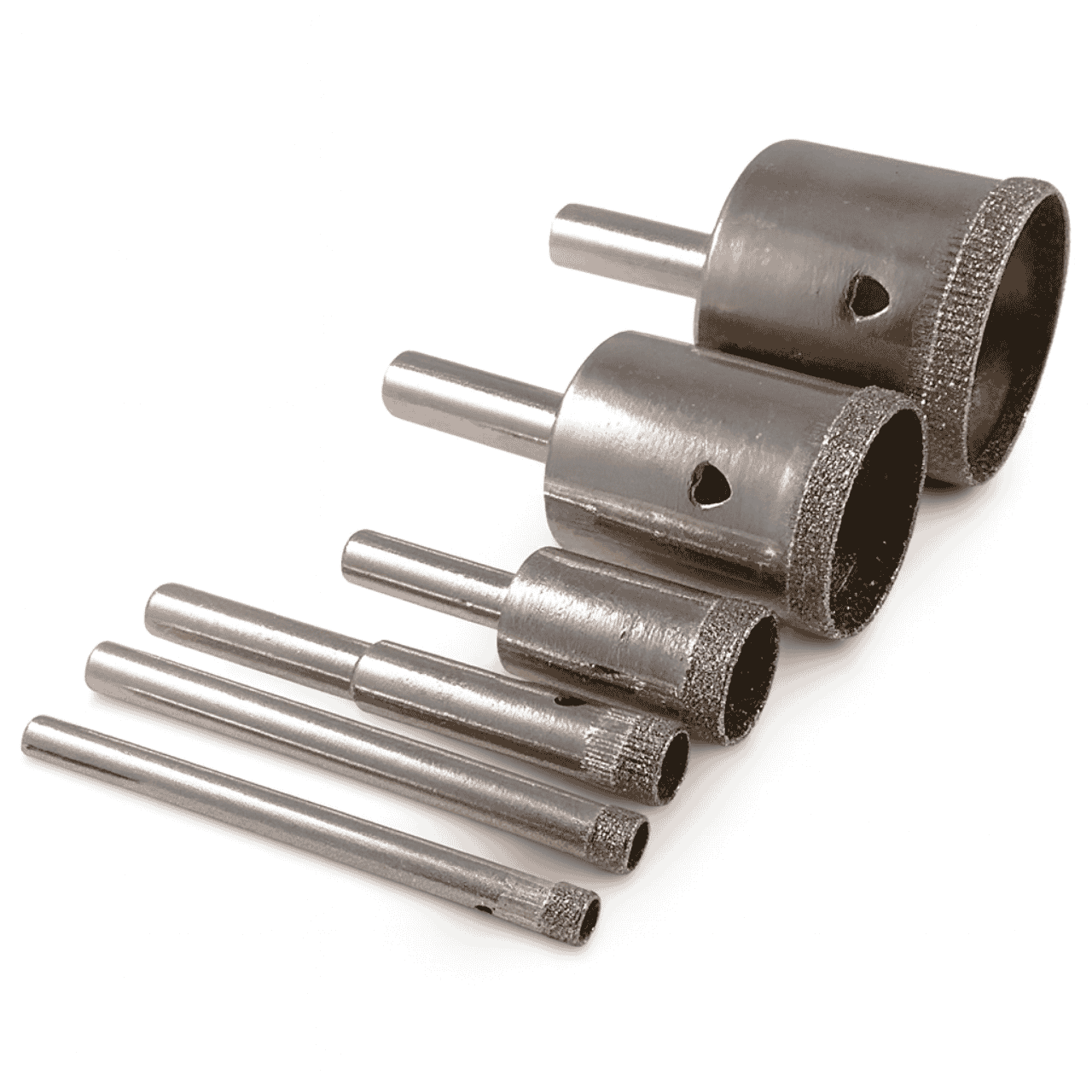

Core Drill Bits

Core Drill Bits: The Complete Guide to Clean, Precise Drilling in Concrete and Masonry

Core drill bits are essential cutting tools used to create perfectly round, smooth, and accurate holes in some of the toughest construction materials. From concrete and reinforced concrete to brick, block, stone, tile, and asphalt, core drill bits are designed to remove a solid cylindrical core instead of breaking or chipping material. This results in cleaner cuts, reduced vibration, and superior structural integrity.

Used across construction, electrical, plumbing, HVAC, mechanical, and civil engineering industries, core drill bits are the professional standard whenever precision, safety, and efficiency matter. Choosing the right core drill bit directly impacts drilling speed, hole quality, and overall project success.

What Are Core Drill Bits?

Core drill bits are hollow, cylindrical cutting tools engineered to drill round holes by grinding through material rather than hammering it. Most core drill bits are embedded with industrial-grade diamonds along the cutting edge, allowing them to cut through extremely hard surfaces with precision and control.

Unlike traditional twist drills or masonry bits, core drill bits extract a solid “core” from the material. This method minimizes cracking, reduces dust, and produces smooth hole walls that are ideal for pipes, conduits, anchors, and ducting.

How Core Drill Bits Work

Core drill bits work by rotating at controlled speeds while applying steady pressure to the drilling surface. The diamond segments on the cutting edge grind through the material gradually, allowing the bit to advance smoothly without damaging surrounding areas.

In many applications, water is supplied directly to the cutting surface. Wet drilling cools the bit, reduces friction, suppresses dust, and flushes debris out of the hole. This not only improves drilling efficiency but also extends the lifespan of the core drill bit.

As the bit penetrates the surface, it removes a cylindrical section of material, leaving behind a precise, clean-edged hole.

Types of Core Drill Bits

Diamond Core Drill Bits

Diamond core drill bits are the most common and versatile option. They are designed for concrete, reinforced concrete, stone, granite, and masonry. The diamond segments provide exceptional cutting performance and durability, even in the hardest materials.

Wet Core Drill Bits

Wet core drill bits are designed to be used with water. They are ideal for concrete and reinforced concrete because water keeps the bit cool, reduces dust, and significantly extends bit life. Wet drilling also produces smoother holes and faster cutting speeds.

Dry Core Drill Bits

Dry core drill bits are used when water is not available or permitted. They are commonly used for brick, block, and softer masonry materials. These bits often feature ventilation slots or segmented designs to help dissipate heat during drilling.

Specialty Core Drill Bits

Specialty core drill bits are engineered for specific materials such as asphalt, tile, ceramic, porcelain, or natural stone. Using a specialty bit ensures clean cuts, prevents surface chipping, and maximizes drilling efficiency for that material.

Materials Core Drill Bits Can Cut

With the correct bit selection, core drill bits can cut through a wide range of materials, including:

-

Reinforced concrete

-

Standard concrete

-

Brick and concrete block

-

Natural stone and granite

-

Asphalt and pavement

-

Tile, porcelain, and ceramic

-

Masonry and composite materials

This versatility makes core drill bits indispensable for contractors and tradespeople working across multiple job types.

Common Applications of Core Drill Bits

Core drill bits are used in a wide range of professional applications. In construction, they are essential for creating openings for plumbing pipes, electrical conduits, fire sprinkler systems, and HVAC ducting.

Mechanical contractors rely on core drill bits for equipment mounting and ventilation penetrations. In civil and infrastructure projects, core drilling is used for bridge decks, roadway installations, utility access points, and anchoring systems.

Because core drilling produces minimal vibration, it is especially suitable for hospitals, schools, data centers, and occupied buildings where noise and structural disturbance must be kept to a minimum.

Choosing the Right Core Drill Bits

Selecting the right core drill bit depends on several important factors. Material type is the most critical consideration, as different materials require different diamond bond hardness and segment designs. Reinforced concrete, for example, requires a bit capable of cutting through both concrete and steel rebar.

Hole diameter and depth also matter. Larger and deeper holes require bits designed for stability and efficient debris removal. Using the correct bit size ensures clean cuts and reduces strain on both the bit and the drilling equipment.

Wet or dry drilling conditions should also be considered. If water is available, wet core drill bits generally provide better performance and longer lifespan. Dry bits are best reserved for materials and situations where water use is restricted.

Advantages of Using Core Drill Bits

Core drill bits offer several advantages over traditional drilling tools. Precision is one of the biggest benefits, as core drill bits produce exact-diameter holes with smooth edges. Reduced vibration protects surrounding structures and minimizes the risk of cracking or spalling.

Dust control is another major advantage, especially when wet drilling is used. Cleaner jobsites improve safety, visibility, and efficiency while reducing cleanup time. Core drilling is also faster and more controlled, making it ideal for professional-grade work.

Safety Guidelines for Core Drill Bits

Safe use of core drill bits starts with proper setup. The drilling equipment should be securely mounted or firmly controlled before drilling begins. Operators should wear appropriate personal protective equipment, including eye protection, gloves, and hearing protection when required.

Water flow must be properly regulated during wet drilling to prevent overheating and excessive wear on the bit. Before drilling, it is essential to verify that there are no embedded utilities, cables, or rebar conflicts in the drilling area.

Applying steady pressure and avoiding excessive force helps prevent bit damage and ensures clean, accurate holes.

Maintenance and Lifespan of Core Drill Bits

Proper maintenance significantly extends the life of core drill bits. After each use, bits should be cleaned to remove slurry, dust, and debris. Allowing buildup to remain on the bit can reduce cutting efficiency and cause uneven wear.

Using the correct drilling speed, maintaining adequate water flow, and avoiding excessive pressure all help preserve diamond segments. Core drill bits should be inspected regularly and replaced when cutting performance declines to maintain professional results.

Core Drill Bits FAQs

What are core drill bits used for?

Core drill bits are used to drill precise, round holes in concrete, masonry, stone, and similar materials for plumbing, electrical, HVAC, and structural applications.

Can core drill bits cut through reinforced concrete?

Yes, diamond core drill bits designed for reinforced concrete can cut through both concrete and embedded steel rebar.

What is the difference between wet and dry core drill bits?

Wet core drill bits are used with water for cooling and dust control, making them ideal for concrete. Dry core drill bits are used for brick or block when water is not available.

How accurate are core drill bits?

Core drill bits are extremely accurate and produce clean holes with exact diameters and smooth walls.

Do core drill bits cause structural damage?

No, core drilling minimizes vibration and stress, making it one of the safest drilling methods for existing structures.

What sizes do core drill bits come in?

Core drill bits are available in a wide range of diameters, from small conduit holes to large openings for piping and ventilation.

How long do core drill bits last?

Bit lifespan depends on material hardness, drilling technique, cooling, and maintenance. Proper use and water flow significantly extend bit life.

Can core drill bits be used indoors?

Yes, especially when wet drilling is used, core drill bits are commonly used indoors due to reduced dust and vibration.

Core drill bits are essential tools for professionals who require clean, precise, and reliable drilling in concrete and masonry. Their accuracy, versatility, and efficiency make them a cornerstone of modern construction, industrial work, and infrastructure projects.